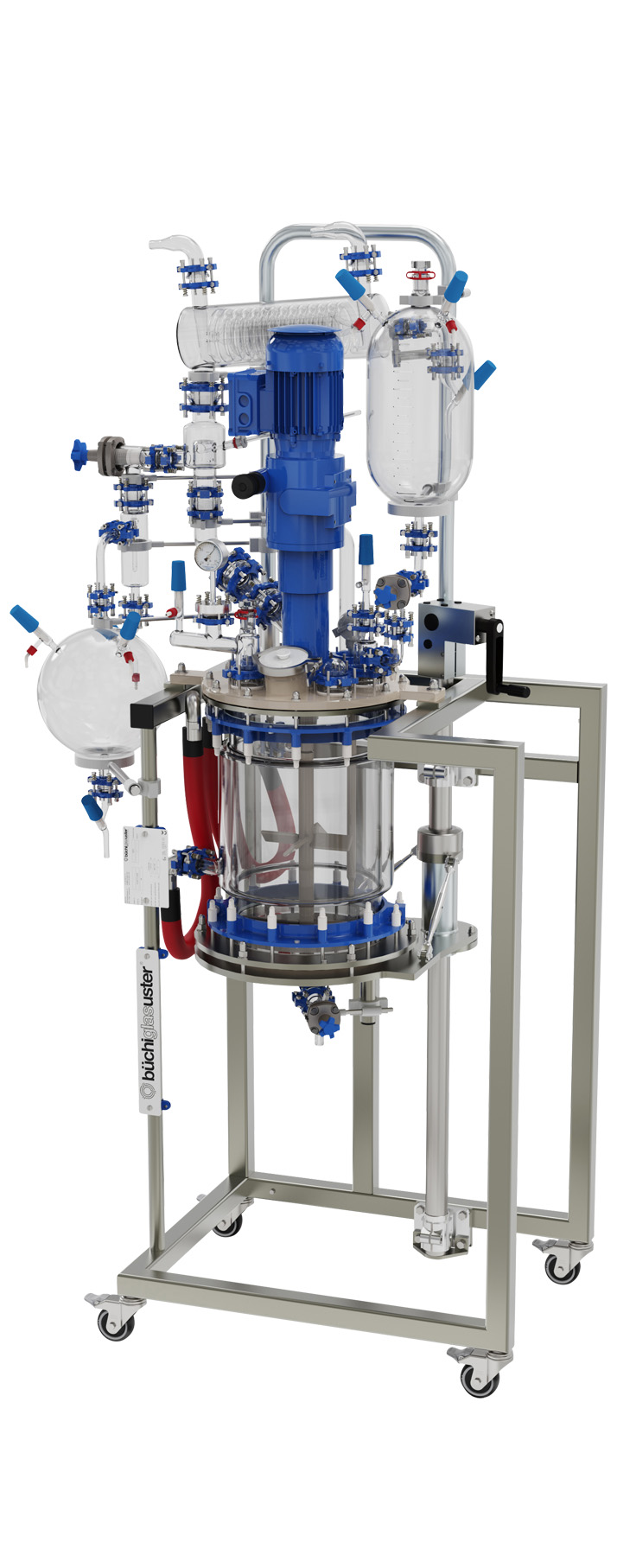

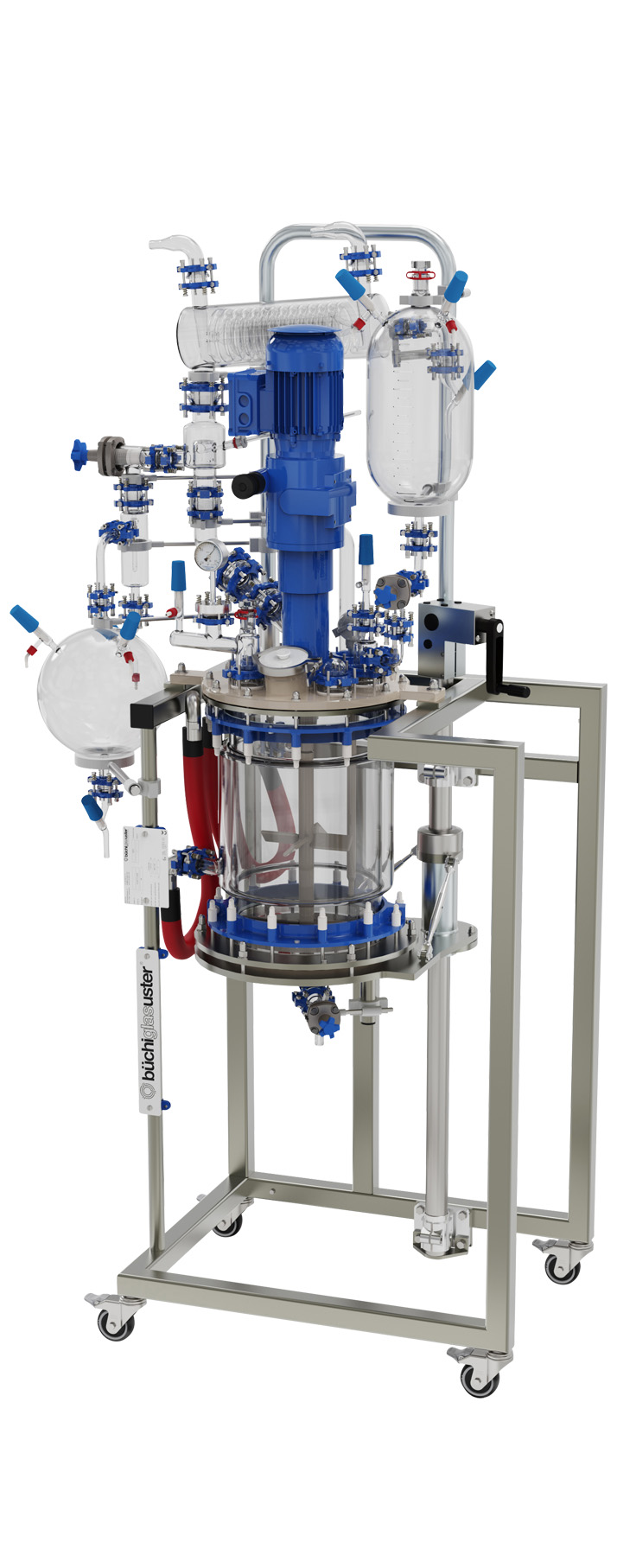

Filter reactors - Buchi FR 10, FR 30 & FR 50

Filter reactors for pilot plants and kilo labs

| Filtration vessel: | 10, 30, 50 liter |

| Pressure FR 10: | -1.0 (FV) to +1.0 bar |

| Pressure FR 30, FR 50: | -1.0 (FV) to +0.5 bar |

| Temperature: | -60/+200 °C |

| Filtration vessel: | 10, 30, 50 liter |

| Pressure FR 10: | -1.0 (FV) to +1.0 bar |

| Pressure FR 30, FR 50: | -1.0 (FV) to +0.5 bar |

| Temperature: | -60/+200 °C |

Our innovative filter reactors are specifically designed for pilot plants and kilo laboratories. These systems combine a reactor and a nutsche filter in a single unit, enabling a wide range of processes and applications, including cGMP API synthesis, peptide synthesis (peptide synthesizer), and cannabis extraction.

The filter reactors are available in three sizes, with 10 liter, 30 liter, and 50 liter reaction volumes. They feature a modular design that allows for easy configuration to meet your specific process requirements.

Our filter reactor systems are distinguished by Swiss Quality, safety, and reliability. They are modular, compact, and mobile, allowing for flexible handling and versatile applications. The straightforward operation and the ability to perform various processes in a single device make them particularly user-friendly.

These systems are turnkey, highly corrosion-resistant, and inert, making them ideal for demanding applications in laboratories and production. Certified to ATEX, CE, and cGMP standards, they offer the highest levels of safety and quality.

Filter reactor for scale-up & pilot plants

Buchi Nutsche filters for reactors & pilot plants

Do you have any questions? Would you like to get in touch with us personally? Ask our specialists. We look forward to hearing from you!