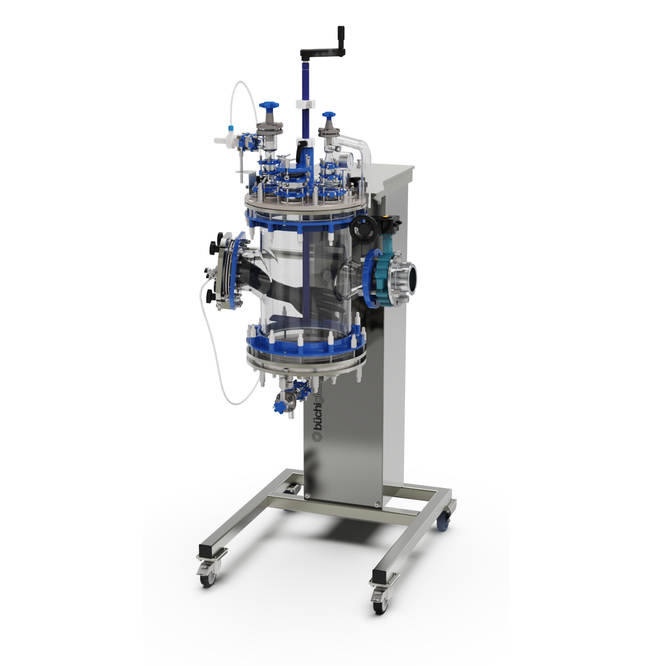

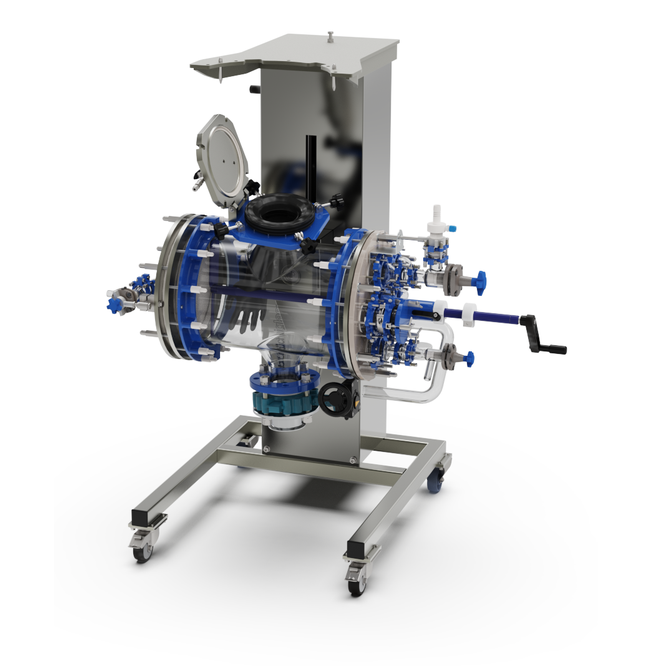

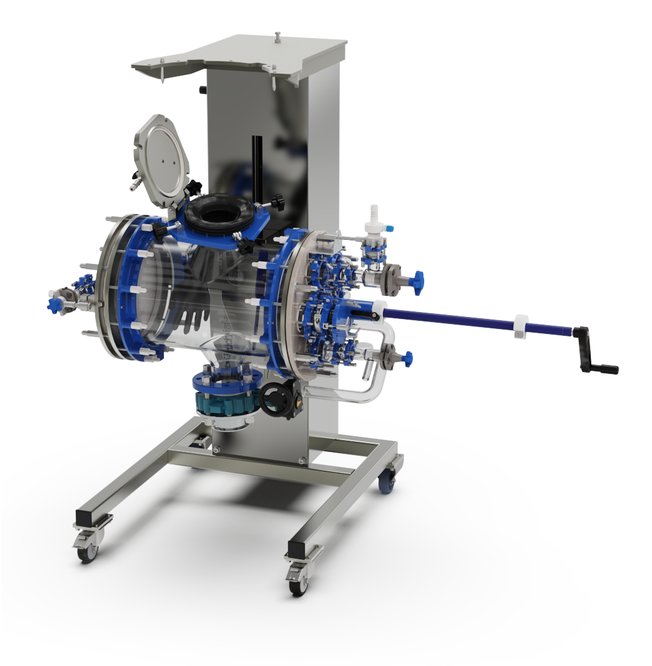

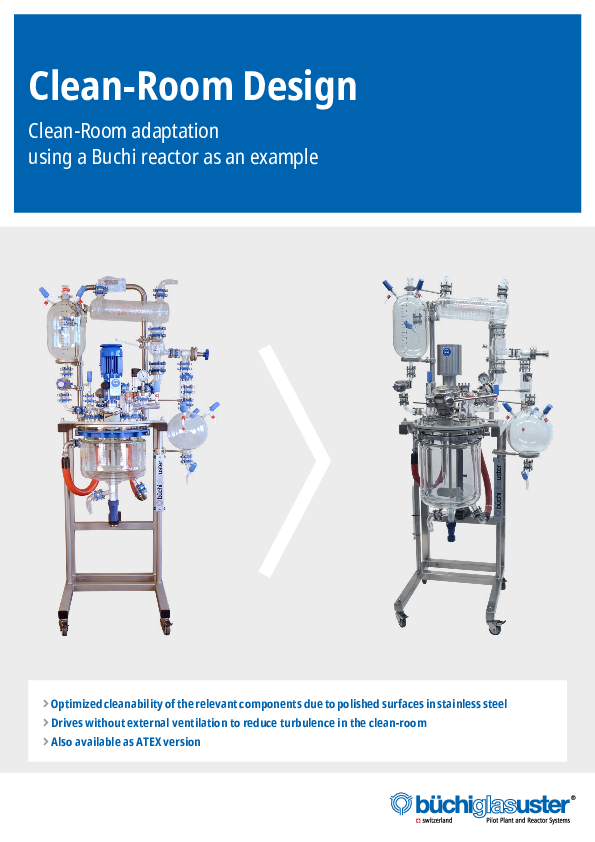

Our systems are customized in accordance with process and operational requirements to provide reliable containment and operational ease for the handling of highly potent APIs in compliance with lowest Occupational Exposure Limits (OELs). The design of the equipment meets the strictest safety and quality requirements while enabling efficient, reproducible, and scalable processes.

Additionally, our HPAPI process systems are integrated seamlessly into isolators (glove boxes) and containment systems. We collaborate with various, leading manufacturers of isolators and containment systems to deliver turnkey solutions in accordance with customer requirements.

Typical HPAPI applications

Equipment for the synthesis and handling of high potency active pharmaceutical ingredients (HPAPIs) are specifically designed for the safe and efficient processing of highly potent molecules in demanding, highly regulated pharmaceutical operations, including:

- Manufacturing of various HPAPIs (from lab, through pilot to production scale)

- Synthesis of cytostatic / cytotoxic molecules

- Manufacturing of antibody-drug conjugates (ADCs)

- Synthesis of toxic loads / payloads for ADCs

- Linker-payload development and synthesis (ADCs)

- Production of hormones and hormone-like substances

- Synthesis of hallucinogenic drug compounds (lab scale)

Key features of HPAPI process equipment

Our HPAPI reactor systems are designed for maximum containment, easy maintenance, and long service life.

Some of the key advantages:

- Maximum tightness and easy cleaning thanks to optimized designs.

- Seamless integration into containment systems or isolators, in cooperation with leading manufacturers.

- Use of high-performance materials, including borosilicate glass 3.3, glass-lined steel, fluoropolymers, and Hastelloy® for outstanding chemical resistance.

- Propietary flexible glass piping system buchiflex for leak-tight connections and maximum flexibility during operation.

Benefits of HPAPI process equipment

Choosing HPAPI reactor systems from Büchi AG offers more than just reliable equipment. These systems are designed to guarantee saftey, efficiency, and compliance at every stage of your process.

Some of the key advantages:

- Fully customized to meet your specific process and operational requirements.

- High cleanability, ensuring consistent product quality batch after batch.

- Maximum operator safety through reliable containment.

- Full compliance with requirements of cGMP and applicable regulations such as ATEX and PED.

- Comprehensive documentation, including IQ/OQ protocols and a quality project plan (QPP), for smooth validation and regulatory approval.